Mecpow MIG-120 Gasless Welding Machine

3-In-1 Multi-Mode Operation

The Mecpow MIG-120 welder supports three welding modes: gasless MIG, MMA, and lift TIG. This versatility makes it perfect for a wide range of applications, from construction and metal fabrication to equipment modification and repair.

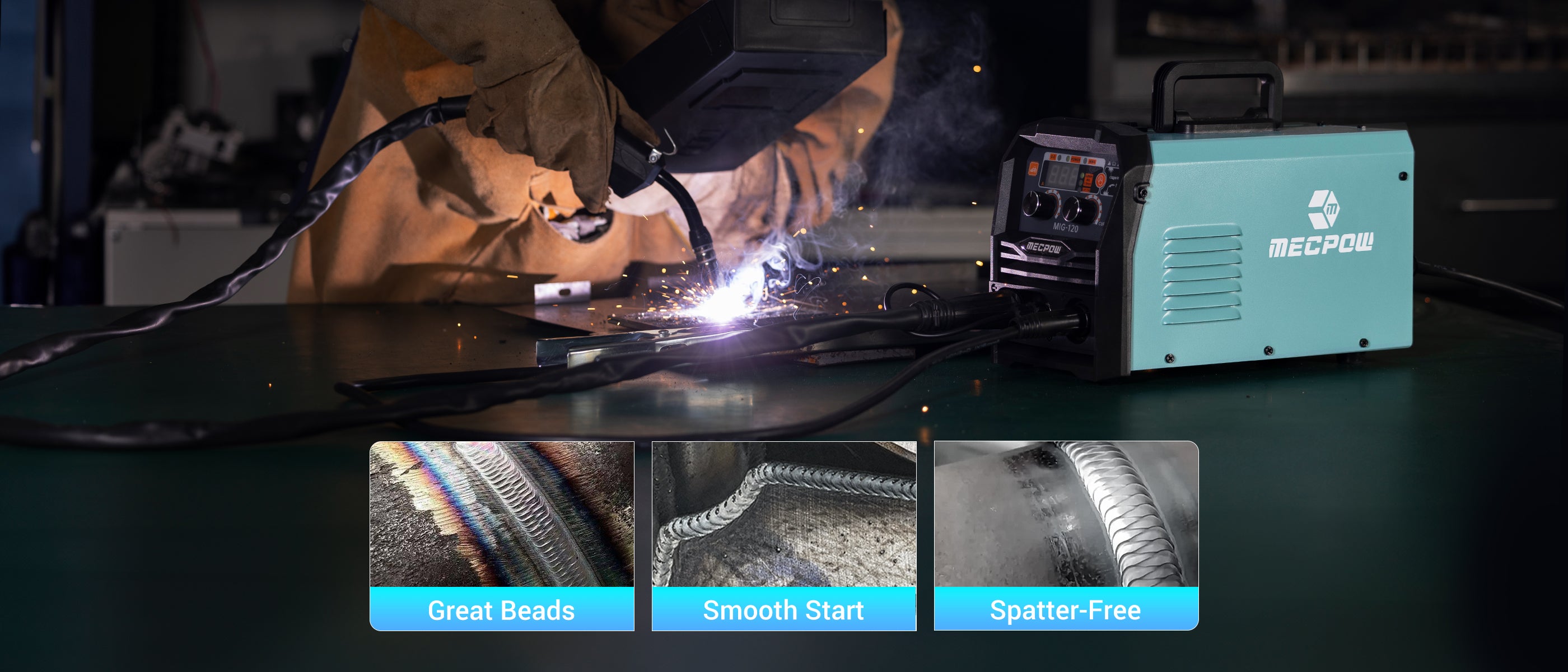

Adjustable Wire Feeding Speed

Experience seamless and uniform wire feeding with adjustable speed settings on the Mecpow MIG-120 welder. This feature ensures high-quality welds without wire jams or feed issues, enhancing overall efficiency and productivity.

Advanced Safety Features

The Mecpow MIG-120 welding machine is equipped with overcurrent, overload, and overheat protection to ensure safe operation and maintain the machine in optimal working condition. The built-in hot start and anti-sticking functions ensure a smooth and stable arc, prevent electrode sticking, and improve welding quality. The fan operates as needed to reduce dust intake and prolong the machine's lifespan.

Precise Control with LCD

The clear LCD screen on the Mecpow MIG-120 welder allows for easy adjustment of welding parameters, including current (20-140A) and wire thickness (0.6-1.0 mm). This precise control ensures optimal welding results and a professional finish.

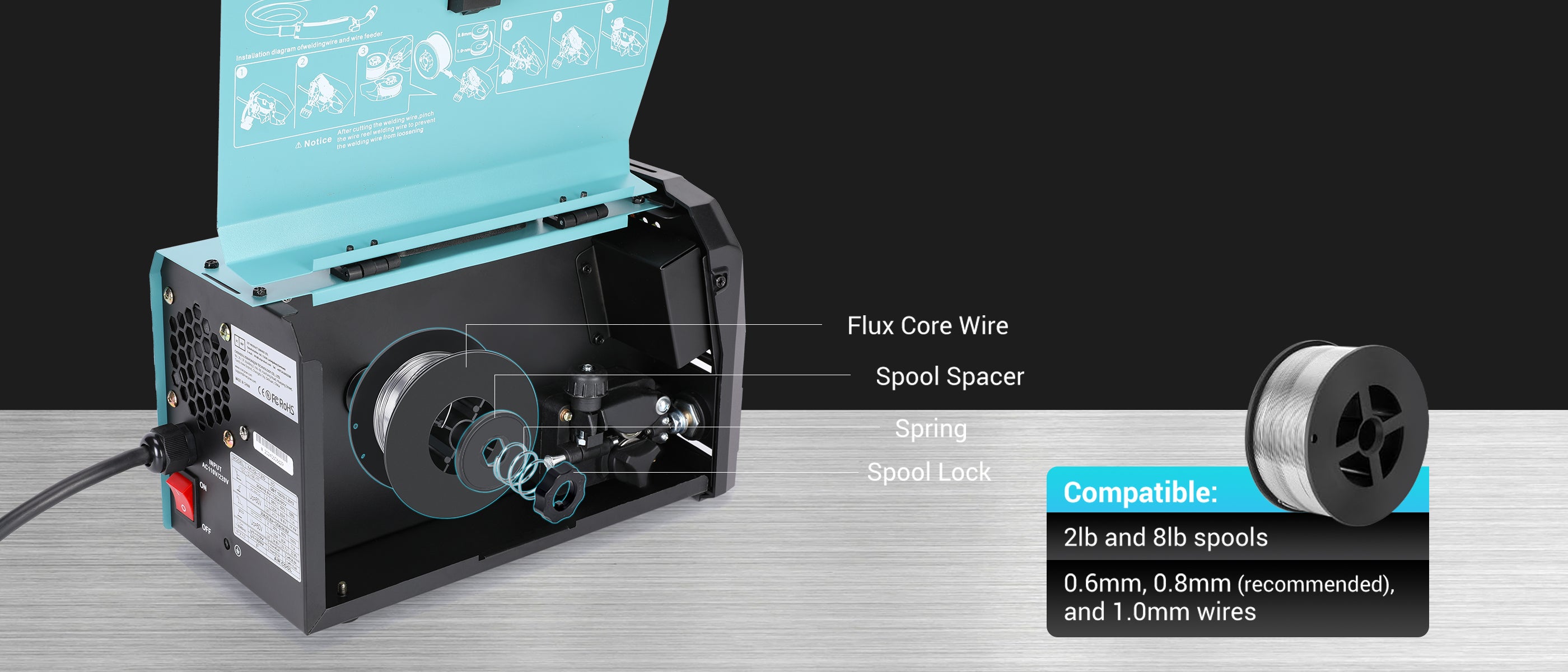

Innovative Flux-Cored Wire

Using flux-cored wire with the Mecpow MIG-120 welding machine eliminates the need for protective gases, making the welding process more convenient and cost-effective. This wire also produces aesthetically pleasing weld seams more efficiently and at higher deposition rates compared to solid wires with gas.

Portable & Lightweight Design

The Mecpow MIG-120 welder is designed with a carrying handle for easy portability, enabling you to take it with you as needed for your projects. Whether for home or outdoor use, it's the perfect choice for you!

LCD Display

Synergic Control

Aluminum Mig

Safety Protection

3-In-1 Welding Machine

*

Perfect for Various Metal Types

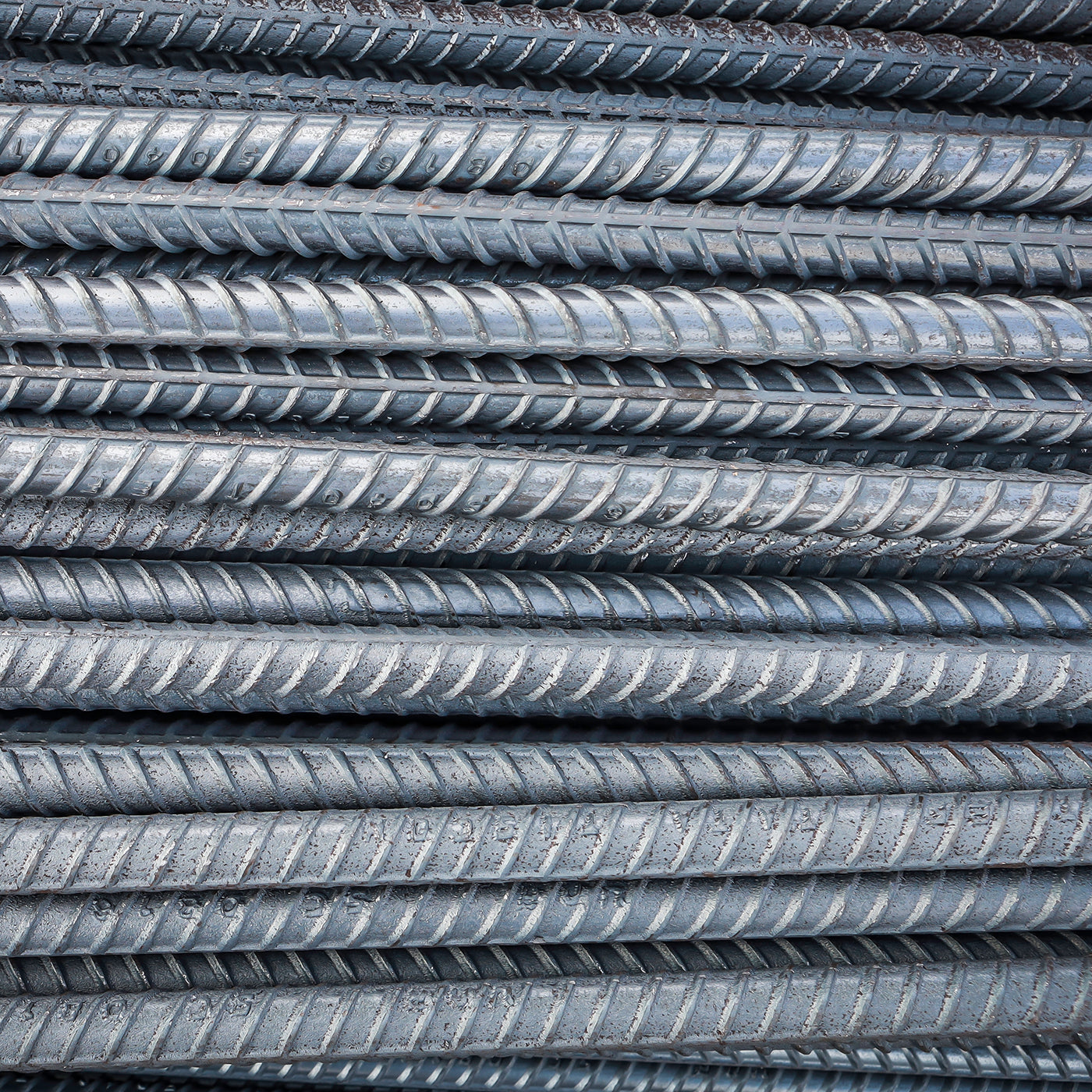

Cast Iron

Mild Steel

Sheet Metal

Carbon Steel

Square Pipe

Stainless Steel

Family DIY

Welding Carport

Machine Manufacturing

Industrial Installation

Package List

Main Machine *1

2m 14AK Welding Torch *1

1.2m 5AWG Wire with200A Ground Clamp *1

1.8m 5AWG Wire with 200A Electrode Holder *1

Wire Brush *1

0.5kg 0.8mm Welding Wire *1

Protective Mask *1

Welding Rod *1

Welding Nozzle *2

User Manual *1

Welding Parameters

|

Welding Type |

Material |

Thickness Range(mm) |

Wire Size |

|

MIG Welding |

Carbon Steel |

/ |

0.30''/0.35'' ER70S-6 mild steel MIG wire and E71-GS flux-cored wire for carbon steel |

|

Stainless Steel |

/ |

0.30''/0.35'' ER308L stainless steel wire |

|

|

MMA(Stick) |

Stainless Steel |

1.0-2.0 |

/ |

|

Mild Steel |

1.0-3.0 |

/ |

|

|

Square Pipe |

0.5-1.0 |

/ |

|

|

Sheet Metal |

5-6 |

/ |

|

|

Carbon Steel |

4-12 |

/ |

|

|

Cast Iron |

Up to 10 |

/ |

|

|

Gasless MIG |

Stainless Steel |

3.0-5.0 |

0.8mm |

|

Mild Steel |

1.6-3.2 |

0.8mm |

|

|

Square Pipe |

3.0-5.0 |

0.8mm |

|

|

Sheet Metal |

3.0-5.0 |

0.8mm |

|

|

Carbon Steel |

2.0-5.0 |

0.8mm |

|

|

Cast Iron |

4.0-6.0 |

0.8mm |

MIG-120 Specification

Brand: Mecpow

Model: MIG-120

Color: Blue

Product Name: Welding Machine

Voltage(V): 220±15% 110±15%

Frequency(Hz): 50/60

Power(KV.A): MMA:5 MIG:4

Input Current(A): MMA:43.4 @110V MMA:21.7@220V

MIG:34.8@110V MIG:17.4@220V

No-load Voltage (V): 60

Rated Output Current(A): MMA:20-120 MIG:36-120

Duty Cycle(%)@ 25 C: 35

Power Factor: 0.7

Efficiency(%): 85

Insulation Class: F

Protection Class: IP21S

Product Weight: 3.61 kg / 7 lb

Package Weight: 5.8 kg / 12.79 lb

Product Size: 32.5 × 16 × 20.5 cm / 12.8 × 6.3 × 8.07 inches

Package Size: 39.6 × 21.2 × 28 cm / 15.59 × 8.35 × 11.02 inches

Main Machine × 1

1.2m 5AWG Wire with 200A Ground Clamp × 1

1.8m 5AWG Wire with 200A Electrode Holder × 1

Wire Brush × 1

2m 14AK Welding Torch × 1

0.5kg 0.8mm Welding Wire × 1

Protective Mask × 1

Welding Rod × 1

Welding Nozzle × 1

User Manual × 1

FAQs for MIG-120

What is a MIG welding machine?

A MIG (Metal Inert Gas) welding machine, also known as GMAW (Gas Metal Arc Welding), uses a continuous wire electrode fed through a welding gun along with a shielding gas to protect the weld pool from contamination. Our MIG welding machines are designed for efficiency and high-quality performance, ensuring clean and strong welds every time.

What materials can I weld with the Mecpow MIG-120 welding machine?

The Mecpow MIG-120 welding machine is highly versatile and can be used to weld a variety of materials, including mild steel, stainless steel, and aluminum.

What are the advantages of using a MIG welding machine?

The advantages of using a MIG welding machine include high welding speed, ease of automation, clean welds with minimal spatter, and the ability to weld both thin and thick materials. Our machines are designed to provide exceptional performance, making your welding tasks faster and more efficient.

What type of gas should I use for MIG welding?

Common shielding gases for MIG welding include argon, carbon dioxide, or a mix of both. The choice depends on the material and desired weld characteristics. We provide guidance on selecting the right gas to achieve the best results with our welders.

Common shielding gases for MIG welding include argon, carbon dioxide, or a mix of both. The choice depends on the material and desired weld characteristics. We provide guidance on selecting the right gas to achieve the best results with our welders.

Setting up the Mecpow MIG-120 involves ensuring proper ventilation, connecting the welding and grounding clamps, and connecting the power supply. Detailed instructions are available in our manual, and our welders are designed for easy setup to get you started quickly and efficiently.

What safety precautions should I take when using a MIG welding machine?

When using a MIG welding machine, always wear protective clothing, gloves, and a welding helmet with a proper shade lens. Ensure good ventilation to avoid inhaling fumes. Our welders are designed with safety in mind, incorporating features that protect you while you work.

Can I use the Mecpow MIG-120 welding machine outdoors?

While MIG welding is typically used indoors due to the need for shielding gas, it can be used outdoors with proper wind protection to prevent the shielding gas from being blown away. Our machines are built to perform well in various environments, ensuring reliable welds even in challenging conditions.

How do I maintain my MIG welding machine?

Regular maintenance includes cleaning the machine, checking and replacing worn contact tips, liners, and nozzles, ensuring proper wire feed, and storing the machine in a dry, dust-free environment. Our welders are designed for easy maintenance, helping you keep them in top condition.

What is the difference between MIG and TIG welding?

MIG welding uses a continuous wire feed and is faster and easier to learn, making it ideal for general use. TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode and provides more precise and high-quality welds but requires more skill. Our range of welders includes both MIG and TIG options to suit your needs.

How does the wire feed speed affect MIG welding?

The wire feed speed controls the rate at which the electrode wire is fed into the weld pool, influencing the weld bead size, penetration, and overall weld quality. Adjusting the wire feed speed is crucial for achieving optimal welding results. Our machines offer precise control over wire feed speed to ensure excellent performance.

Do Mecpow MIG welders support TIG welding?

Yes, Mecpow MIG welders support lift TIG welding with an additional TIG torch.

Can I use other torches with the welder?

We recommend using the torch that comes with the welder. For MIG welders, our machines are compatible with all European connector MIG torches.

Can I use a spool gun with Mecpow MIG welders?

Yes, our MIG welders are compatible with a spool gun for easier and more efficient welding.